Easy Tips For Using Viscosity Improvers In Different Industries

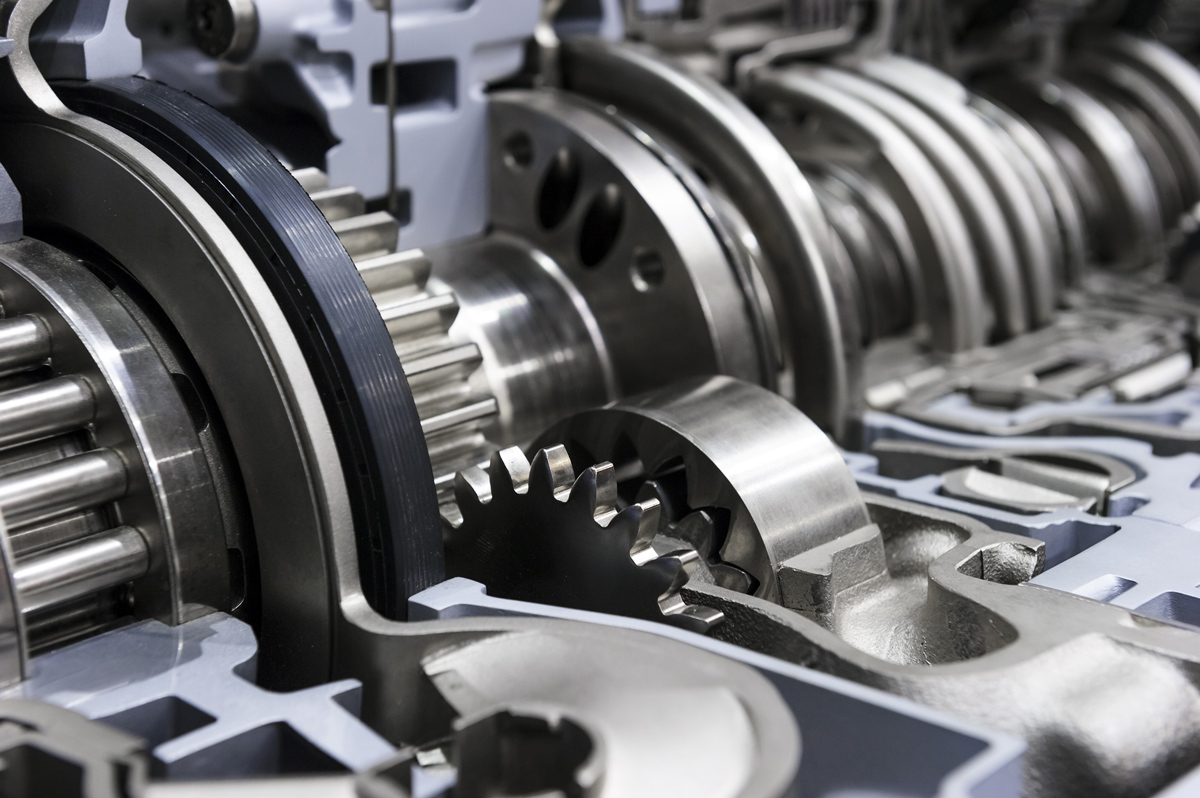

Viscosity improvers are essential additives used across various industries, including automotive, aerospace, and manufacturing, to improve the performance of lubricants, oils, and other products. These additives help maintain the desired viscosity under different temperature and pressure conditions. Find here some easy tips for effectively using viscosity improver polymers in various industries.

Understand the application requirements:

Before incorporating viscosity improvers into your formulations, it’s essential to understand the specific requirements of your application. Different industries have varying standards and expectations for lubricant performance. For example, automotive engine oils need to perform well in both cold starts and high-temperature conditions, while hydraulic fluids may require a more stable viscosity under pressure.

Choose the right type of viscosity improver:

There are several types of viscosity improvers, including polymeric and non-polymeric options. Polymeric viscosity improvers, such as polyisobutylene or polymethacrylate, are widely used due to their effectiveness in a broad temperature range. Non-polymeric alternatives may be suitable for specific applications. Research the characteristics of each type and select one that aligns with your product’s performance needs.

Conduct compatibility tests:

Compatibility with base oils and other additives is vital to ensuring the effectiveness of viscosity improvers. Perform compatibility tests by mixing the viscosity improver with the base oil to observe any adverse reactions, such as separation or precipitation. This step is particularly important in applications where multiple additives are used.

Monitor environmental conditions:

Environmental factors such as temperature and humidity can significantly impact the performance of viscosity improvers. Ensure that the storage and application environments are controlled to maintain the integrity of the additives. High temperatures can lead to degradation, while excessive moisture may affect the viscosity improver’s effectiveness. Regularly check storage conditions and maintain optimal environments for your products.

Test for performances stability:

After incorporating viscosity improvers, conduct stability tests to evaluate the performance of your final product over time. Monitor key parameters like viscosity, shear stability, and thermal resistance to ensure that the product meets quality standards. Regular testing will help identify any issues early, allowing for adjustments to improve performance.

Using viscosity improvers effectively can significantly improve the performance and reliability of lubricants and other products across various industries. By understanding application requirements, choosing the right type of improver, following dosage guidelines, conducting compatibility tests, monitoring environmental conditions, and testing for performance stability, you can ensure optimal results and maintain high standards in your formulations.